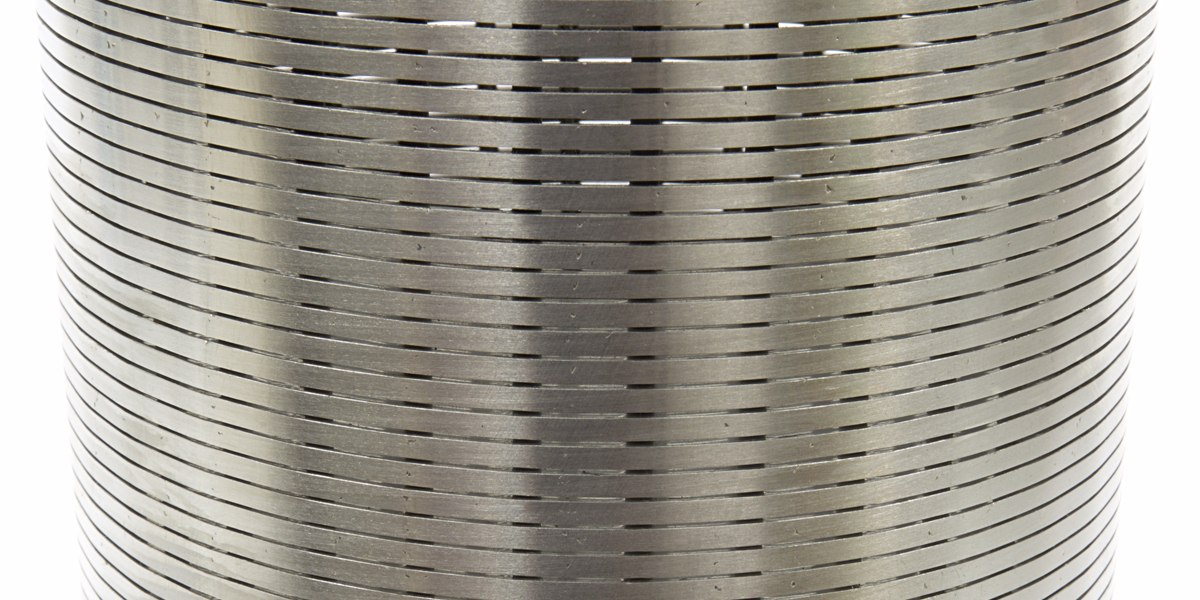

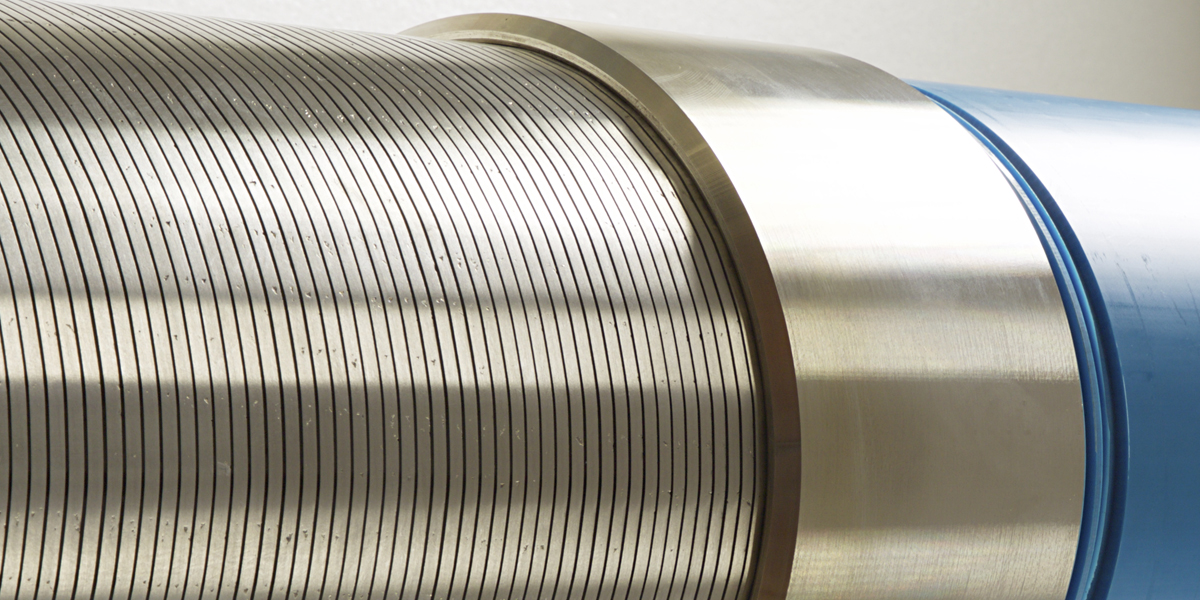

Continuous spiral filters

Spiroscreen is the range of continuous spiral filters entirely produced by GTS from DN100 to DN600.

The filters are constructed by continuously winding, with a controlled pitch, a triangular section profile on round profiled conductors, each intersection between triangular and round profile is resistance welded (RW).

Spiral filters in stainless steel

Spiral filters in stainless steel SPIROSCREEN from DN100 to DN600

ADVANTAGES

- HIGH FILTRATION EFFICIENCY

- HIGH PERFORMANCE

MATERIAL

The construction is in stainless steel, a first choice material to withstand the stresses during installation, pressure and corrosion.

FEATURES

The spiral filters are characterized by a wide surface of passage that allows to obtain high flow rates while keeping the water speed at the inlet very low.

This allows the optimal development of the well:

- Minimum hydraulic resistance

- Reduction of scale formation

- Less entry of impurities (sand) that can damage the pump over time

- Rapid and complete drilling fluid removal.

DIMENSIONI E SPECIFICHE

- from DN100 to DN600

- 3 levels of resistance to collapse pressure

- Configurable slot based on the granulometric curve

- Stainless steels in AISI 304 1.4301 or AISI 316 1.4404 grade

- Joints: to be welded

– Threaded M / F (metric trapezoidal or API type)

PERMEABILITY

| Diameter (mm) | Profile series | Slot (mm) | |||||

|---|---|---|---|---|---|---|---|

| 0,3 | 0,5 | 0,7 | 1 | 1,5 | 2 | ||

| 114 | 250 | 1,15 | 1,79 | 2,35 | 3,07 | 4,03 | 4,78 |

| 114 | 300 | 0,98 | 1,53 | 2,03 | 2,69 | 3,58 | 4,30 |

| 139 | 250 | 1,40 | 2,18 | 2,87 | 3,74 | 4,91 | 5,82 |

| 139 | 300 | 1,19 | 1,87 | 2,48 | 3,28 | 4,37 | 5,24 |

| 139 | 350 | 1,03 | 1,64 | 2,18 | 2,91 | 3,93 | 4,76 |

| 168 | 250 | 1,70 | 2,64 | 3,46 | 4,52 | 5,94 | 7,04 |

| 168 | 300 | 1,44 | 2,26 | 3,00 | 3,96 | 5,28 | 6,33 |

| 168 | 350 | 1,25 | 1,98 | 2,64 | 3,52 | 4,75 | 5,76 |

| 219 | 250 | 2,21 | 3,44 | 4,52 | 5,90 | 7,74 | 9,17 |

| 219 | 300 | 1,88 | 2,95 | 3,90 | 5,16 | 6,88 | 8,26 |

| 219 | 350 | 1,63 | 2,58 | 3,44 | 4,59 | 6,19 | 7,51 |

| 219 | 400 | 1,44 | 2,29 | 3,07 | 4,13 | 5,63 | 6,88 |

| 244 | 300 | 2,09 | 3,29 | 4,35 | 5,75 | 7,67 | 9,20 |

| 244 | 350 | 1,82 | 2,87 | 3,83 | 5,11 | 6,90 | 8,36 |

| 244 | 400 | 1,60 | 2,56 | 3,43 | 4,60 | 6,27 | 7,67 |

| 273 | 300 | 2,34 | 3,68 | 4,87 | 6,43 | 8,58 | 10,29 |

| 273 | 350 | 2,03 | 3,22 | 4,29 | 5,72 | 7,72 | 9,36 |

| 273 | 400 | 1,80 | 2,86 | 3,83 | 5,15 | 7,02 | 8,58 |

| 273 | 450 | 1,61 | 2,57 | 3,46 | 4,68 | 6,43 | 7,92 |

| 323 | 300 | 2,77 | 4,35 | 5,76 | 7,61 | 10,15 | 12,18 |

| 323 | 350 | 2,40 | 3,81 | 5,07 | 6,76 | 9,13 | 11,07 |

| 323 | 400 | 2,12 | 3,38 | 4,53 | 6,09 | 8,30 | 10,15 |

| 323 | 450 | 1,90 | 3,04 | 4,10 | 5,53 | 7,61 | 9,37 |

| 355 | 350 | 2,64 | 4,18 | 5,58 | 7,44 | 10,04 | 12,17 |

| 355 | 400 | 2,33 | 3,72 | 4,98 | 6,69 | 9,12 | 11,15 |

| 355 | 450 | 2,09 | 3,35 | 4,50 | 6,08 | 8,36 | 10,29 |

| 406 | 350 | 3,02 | 4,78 | 6,38 | 8,50 | 11,48 | 13,91 |

| 406 | 400 | 2,67 | 4,25 | 5,70 | 7,65 | 10,44 | 12,75 |

| 406 | 450 | 2,39 | 3,83 | 5,15 | 6,96 | 9,57 | 11,77 |

| 508 | 400 | 3,34 | 5,32 | 7,13 | 9,58 | 13,06 | 15,96 |

| 508 | 450 | 2,99 | 4,79 | 6,45 | 8,71 | 11,97 | 14,73 |

| 609 | 400 | 4,00 | 6,38 | 8,55 | 11,48 | 15,65 | 19,13 |

| 609 | 450 | 3,59 | 5,74 | 7,73 | 10,44 | 14,35 | 17,66 |

OPEN AREA

| 250 | 300 | 350 | 400 | 450 | Profile series | |||

| 2,5 x 2,38 | 3 x 3,65 | 3,5 x 5 | 4 x 7,25 | 4,5 x 9,25 | L x H [mm] | |||

| slot [mm] | 0,3 | 10,70% | 9,10% | 7,90% | 7,00% | 6,30% | Open Area % | |

| 0,5 | 16,70% | 14,30% | 12,50% | 11,10% | 10,00% | |||

| 0,7 | 21,90% | 18,90% | 16,70% | 14,90% | 13,50% | |||

| 1 | 28,60% | 25,00% | 22,20% | 20,00% | 18,20% | |||

| 1,5 | 37,50% | 33,30% | 30,00% | 27,30% | 25,00% | |||

| 2 | 44,40% | 40,00% | 36,40% | 33,30% | 30,80% | |||