Spiroscreen is the range of continuous spiral filters entirely produced by GTS. It is mostly used in the geothermal sector, in the field of environmental remediation, water wells, for industrial use and from today also in the field of design.

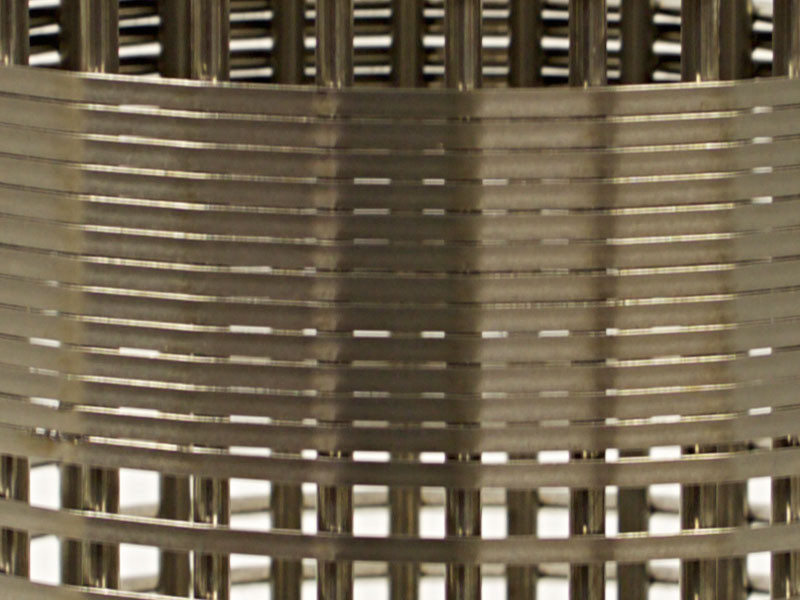

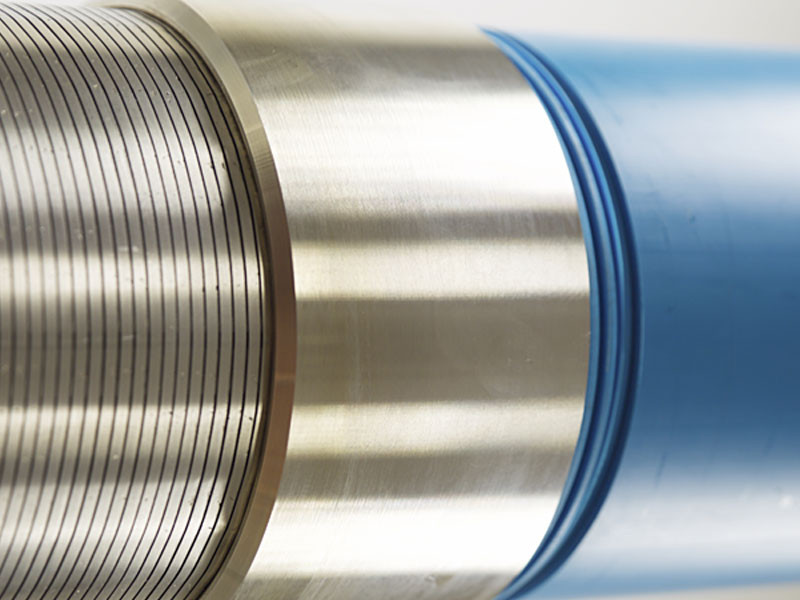

The filters are constructed by continuously wrapping a triangular section profile on round profiled sections with controlled pitch, offering multiple advantages including high filtering efficiency and high performances.

Guarantee and Quality

Iso 9001 – REG (CE) N. 1935/2004 EU

A brand and an Italian product with European standards and certifications

Production

How Spiroscreen is made

The filters are made with an automatic numerical control machine, the construction takes place by continuously wrapping the triangular profile on the round section lines. Each crossing point between the directrix and the profile is resistance-welded (RW) where the two profiles, after the localized fusion in the single point of contact, partially interpenetrate, forming a single body maintaining the original mechanical resistances. Through the machine software the management of all the parameters that characterize the filters takes place, in particular the step that generates the passage light (slot), where by means of a retroactive measuring system the machine is able to perform any corrections in real time to keep the repeatability of the slots constant.

Fields of use

Where and how Spiroscreen can be used